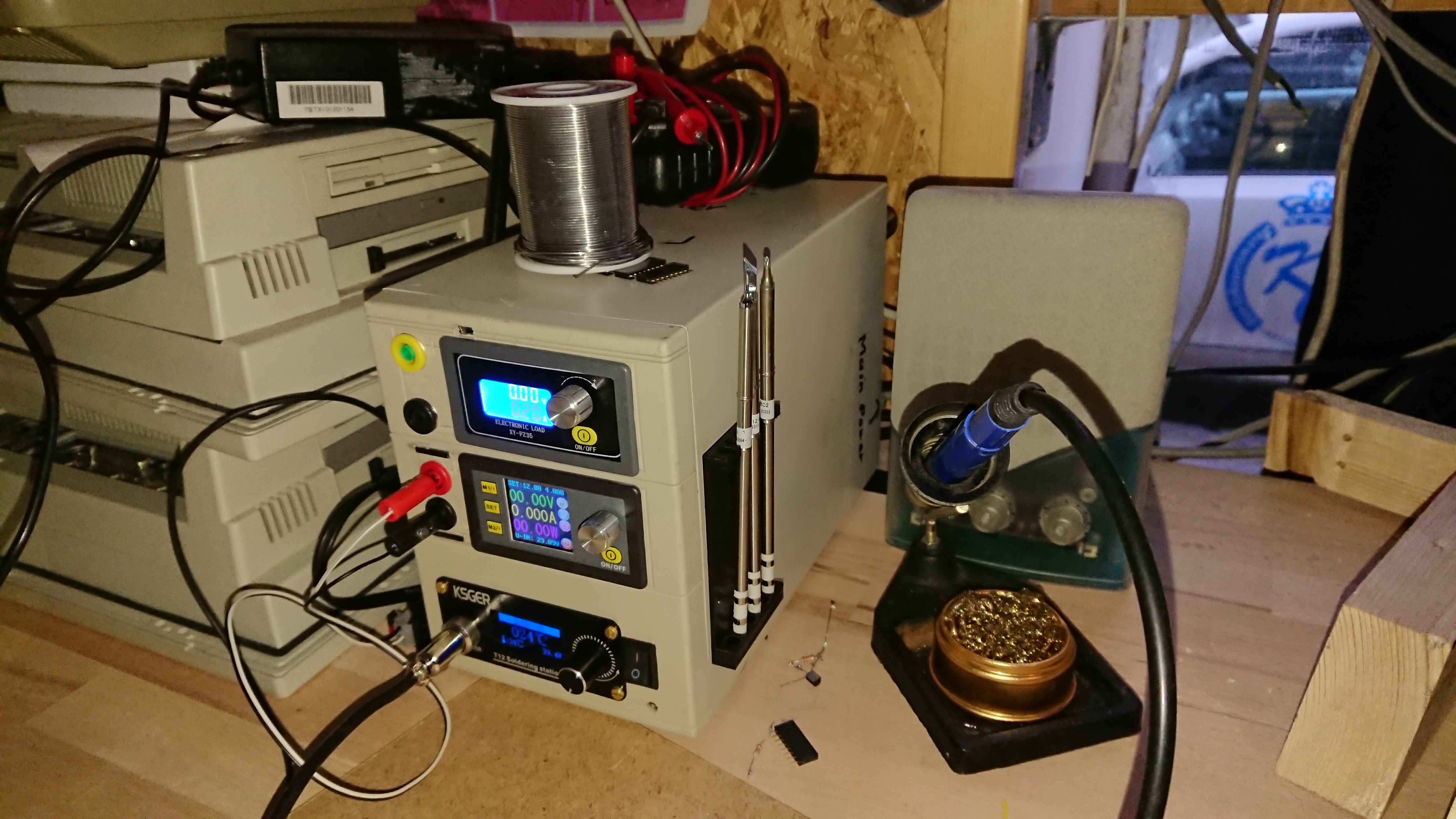

Our mini electronics all-in-one box for LoTHR (so people in LoTHR don’t have to walk all the way to TESLA for the quick and small stuff), got an upgrade.

The previously empty top slot now features an XY-FZ35 programmable electronic load. Test your power supply, test your batteries capacity, draw a discharge graph, use it in ways not intended by it’s makers. (But if you break or brick it, You Replace And Fix It ASAP!)

The tiny cut-out on the top left of the load, features a mini-USB jack where we put an USB serial-TTL converter connected to the GND,TX,RX pins of the load. Using the easy command-set you can indeed periodically poll your batteries discharge rate, voltage on so on.

But even without USB, the thing is pretty nifty and allows you to set a limit on the amount of mAh to draw, or to stop after a specified time, and so on.